- Certified ISO 9001 : 2015

- Download Catalogue

- Unit No. 327, Pride Industrial Estate,

Near Waliv Phata, Sativali Road, Vasai East,

Tal : Vasai, Dist. Palghar-401208, Maharashtra, India

- +91 9326474970

- enquiry@supercastind.com

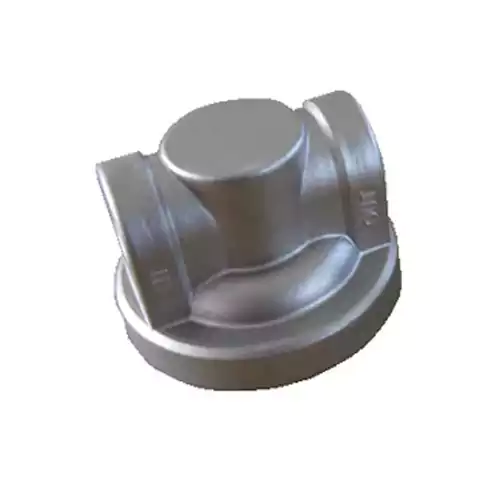

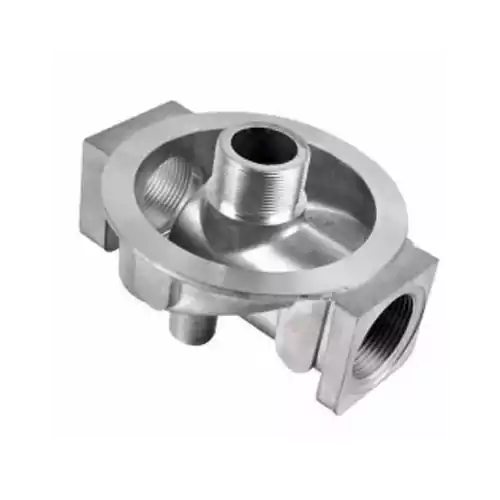

Supercast International is a leading manufacturer of investment castings for the valve industry including valve parts and components. With extensive experience in fabricating castings for valves used across various industries, we specialize in creating high quality valve components. We offer a wide range of valve types and sizes, having successfully manufactured numerous varieties to meet industry demands. Our technical experts who are proficient in their respective fields are credited with the quality of the castings for our valve components.

Product Details:

Investment casting for valve components is a sophisticated manufacturing process that involves several precise steps to create high quality metal parts. The process begins with the creation of a wax pattern that mirrors the desired valve component. This wax pattern is then coated with a ceramic material to form a shell which is subsequently heated. The heating causes the wax to melt and drain away, leaving behind a hollow ceramic mold. Once the mold is prepared, molten metal is poured into it, filling the cavity left by the wax. After the metal cools and solidifies, the ceramic shell is broken away, revealing the finished valve component. This method works well for creating detailed designs and complicated shapes often used in valve manufacturing. Investment casting for valve components provides accuracy and smooth surfaces which are important for applications requiring high performance and reliability. The ability to cast components from various alloys such as stainless steel and aluminum further enhances its applicability across different industries.

However, the investment casting for valve components process requires careful control of different parameters such as temperature and cooling rates to ensure that defects like porosity do not occur in the final product. The versatility of investment casting for valve components also extends to its capacity for small scale production runs, making it an attractive option for manufacturers looking to create limited quantities of specialized valve components. Furthermore, the efficiency of materials in this particular process reduces waste during production, adhering to sustainability focused manufacturing trends.

Investment casting for valve components has established itself as a preferred choice for industries such as aerospace and medical devices, where precision engineering is crucial. By utilizing advanced techniques and materials, manufacturers can meet stringent industry standards while delivering high performance valve components that fulfill specific operational requirements. As technology evolves, innovations in investment casting processes continue to emerge, enhancing capabilities and expanding potential applications in valve manufacturing. This adaptability ensures that investment casting for valve components remains a vital method for producing components that meet the ever increasing demands of modern engineering challenges.

Components of Investment Casting for Valve Components:

1.Wax Pattern: The initial component of Investment Casting for Valve Components is the wax pattern, which is an identical model of the valve component to be produced.

2. Ceramic Shell: After creating the wax pattern, it is coated with a ceramic material to form a shell that will serve as the mold for casting.

3.Wax Removal: The ceramic shell is heated to melt and drain away the wax, leaving a hollow mold that captures the complex details of the pattern in Investment Casting for Valve Components.

4.Metal Pouring: Molten metal is poured into the ceramic mold to form the valve component, filling the cavity left by the wax during the process.

5.Cooling and Solidification: Once the metal is poured, it is allowed to cool and solidify, taking the shape of the mold formed in investment casting for valve components.

6.Shell Removal: After cooling, the ceramic shell is broken away to reveal the cast valve component which is a crucial step in the complete process.

7.Finishing Processes: The cast component may undergo various finishing processes such as machining, polishing or surface treatment to achieve desired specifications and surface quality.

8.Quality Control: Throughout the process, quality control measures are implemented to ensure that the final product meets industry standards and specifications.

Application Industries:

1.Oil and Gas Industry

2.Chemical Industry

3.Hydropower Plants

4.Mining Industry

5.Nuclear Industry

6.Agriculture

7.Firefighting Equipment

8.Pharmaceutical Industry

9.Food Processing Industry

10.Construction Industry

Investment casting is a highly effective process for producing precision valve bodies that are essential in controlling the flow of liquids and gases across a variety of industries. Its ability to handle complex geometries, high precision, and a broad range of materials makes it the preferred choice for manufacturing valve bodies, especially those that need to withstand high pressure, extreme temperatures, and corrosive environments. By providing high-strength, durable, and corrosion- resistant parts, investment casting ensures that valve bodies perform reliably and efficiently in critical applications such as oil and gas, chemical processing, power generation, and water treatment systems.